Discover High-Quality Bobcat Aftermarket Parts for Superior Efficiency

Discover High-Quality Bobcat Aftermarket Parts for Superior Efficiency

Blog Article

Unlocking Potential: Aftermarket Parts as a Cost-efficient Option for Machinery and Heavy Tools

In the ever-evolving landscape of equipment and hefty devices upkeep, the application of aftermarket components has actually arised as an engaging alternate worth checking out. These parts, usually overlooked in support of initial devices producer (OEM) parts, present an affordable remedy that warrants focus. While the concept might increase brows amongst traditionalists, the benefits that aftermarket components supply in terms of price savings, high quality, and performance are not to be ignored. As markets seek ways to take full advantage of and enhance procedures efficiency, the prospective unlocked by aftermarket components positions intriguing possibilities that can reshape established methods and generate considerable benefits.

Expense Savings and Worth Proposal

The cost financial savings and worth recommendation of using aftermarket components for equipment and heavy equipment are substantial elements that add to functional performance and financial viability in different sectors. By choosing aftermarket parts over initial tools maker (OEM) parts, organizations can recognize considerable cost savings without endangering on quality or efficiency. Aftermarket parts are typically more competitively priced than their OEM equivalents, allowing firms to reduce upkeep and repair work expenditures while still ensuring the correct performance of their machinery and tools.

These parts are widely readily available and supply a more comprehensive selection compared to OEM components, supplying companies with greater flexibility and ease in sourcing the elements they require. Furthermore, aftermarket parts are recognized for their high top quality and dependability, conference or also going beyond sector requirements in many instances.

High Quality and Compatibility Guarantee

When taking into consideration the usage of aftermarket components for machinery and hefty tools,Highlighting the paramount relevance of quality control and compatibility confirmation is important. Ensuring that aftermarket parts go beyond or meet market standards for high quality is critical to preserving the optimum efficiency and long life of the machinery. Quality control measures, such as extensive screening treatments and certifications, supply reassurance to devices proprietors that the aftermarket components will work dependably and successfully.

Raised Schedule and Alternatives

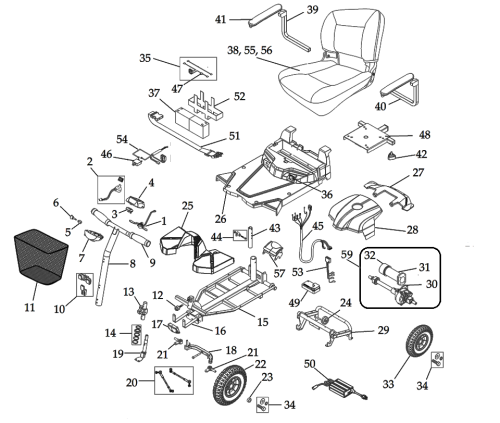

With an expanding market and growing demand, aftermarket parts for machinery and hefty tools are now providing increased schedule and a wider series of alternatives to accommodate the diverse needs of tools owners. This rise in schedule is driven by the aftermarket parts sector's commitment to satisfying the certain demands of numerous equipment brands and versions. Equipment proprietors can currently access a large range of aftermarket components, ranging from engine components to hydraulic components, electrical systems, undercarriage elements, and more.

In addition, aftermarket parts manufacturers are continually expanding their line of product to include components for a broader range of equipment and heavy tools, making sure that owners can discover suitable replacements no matter of the equipment kind or model they have. This increased accessibility and variety of aftermarket parts encourage tools owners to make cost-efficient decisions without endangering on quality or performance. Because of this, they can effectively preserve, fix, and upgrade their equipment with confidence, understanding that aftermarket components supply a trustworthy choice to OEM components.

Efficiency and Resilience Perks

Enhancing equipment and heavy equipment with aftermarket parts brings significant efficiency and resilience benefits to tools proprietors. Aftermarket components are frequently created with innovations in technology and materials, offering enhanced performance contrasted to initial tools manufacturer (OEM) parts. Upgraded components can result in enhanced power, performance, and total machine capabilities, resulting in improved productivity and operational effectiveness.

Furthermore, aftermarket parts are often crafted to be a lot more long lasting and durable than their OEM equivalents. This raised durability can translate to reduced downtime for maintenance and repairs, inevitably helpful site conserving devices proprietors important money and time. By buying aftermarket parts known for their toughness, machinery and heavy equipment can withstand rough operating problems and hefty workloads with greater strength.

Essentially, the performance and sturdiness benefits of aftermarket components contribute dramatically to maximizing the performance and long life of equipment and hefty tools. Tools owners stand to gain an affordable side by leveraging aftermarket remedies to improve the total efficiency and toughness of their properties.

Sustainability and Environmental Impact

The application of aftermarket parts not just boosts the efficiency and longevity of equipment and heavy devices but likewise plays a crucial role in resolving sustainability issues and decreasing environmental effect. By opting for aftermarket parts, industries contribute to the reduction of waste generation considering that these components are often sourced from recycled materials or through remanufacturing procedures. This practice lines up with the concepts of a circular economic situation, where resources are utilized successfully, and waste is decreased.

Moreover, aftermarket parts can expand the life expectancy of machinery and tools, lowering the frequency of substitutes and as a result decreasing the general carbon footprint related to manufacturing new machinery. Additionally, the manufacturing of aftermarket parts usually involves less power consumption and less exhausts compared to manufacturing original tools maker (OEM) components - Bobcat Aftermarket Parts. This change to aftermarket components sustains eco-friendly techniques by advertising reusability and source conservation within the industrial sector. Ultimately, the combination of aftermarket components right into machinery repair and maintenance is a lasting technique that benefits both companies and the anonymous setting.

Verdict

To conclude, aftermarket parts supply a cost-effective option for equipment and heavy equipment by offering expense financial savings, quality control, raised schedule, efficiency advantages, and sustainability benefits. These components not just offer a feasible choice to initial devices producer parts but additionally contribute to the general performance and durability of equipment and devices. Welcoming aftermarket parts can bring about significant cost financial savings and boosted efficiency, making them a valuable alternative for businesses aiming to optimize their resources.

By choosing for aftermarket components over original devices producer (OEM) parts, services can recognize substantial price financial savings without compromising on top quality or efficiency (Bobcat Aftermarket Parts). Equipment owners can currently access a large array of aftermarket parts, ranging from engine parts to hydraulic parts, electrical systems, undercarriage parts, and more

Additionally, aftermarket parts producers are continuously broadening their product lines to include parts for a wider range of machinery and hefty tools, making sure that proprietors can find ideal substitutes no matter of the tools kind or version they have. Aftermarket components are typically created with innovations in technology and materials, offering enhanced efficiency compared to original devices supplier (OEM) parts. Furthermore, the production of aftermarket parts commonly involves less power intake and less emissions visit their website compared to manufacturing initial equipment supplier (OEM) parts.

Report this page